Optimal Timing for Stamped Concrete Service

Choosing the optimal time for stamped concrete service depends on climate conditions, project scope, and desired results. Proper timing ensures the concrete cures correctly and achieves the best appearance and durability.

Spring and early fall are optimal for stamped concrete due to moderate temperatures and lower humidity, reducing the risk of curing issues.

Avoid extreme heat, cold, or rain. High temperatures can cause rapid drying, leading to cracking, while cold weather hinders proper curing.

The recommended temperature range for stamped concrete installation is between 50°F and 85°F for optimal curing and finishing.

Scheduling during dry, mild days minimizes delays and ensures consistent results throughout the project.

Spring offers moderate temperatures ideal for consistent curing and vibrant color application.

Early fall provides cooler weather, reducing the risk of rapid drying and cracking during installation.

Cold temperatures can delay curing and affect the final appearance of stamped concrete.

Scheduling during dry weather prevents water damage and ensures proper setting of the concrete.

Ways to make Stamped Concrete Service work in tight or awkward layouts.

Popular materials for Stamped Concrete Service and why they hold up over time.

Simple add-ons that improve Stamped Concrete Service without blowing the budget.

High-end options that actually feel worth it for Stamped Concrete Service.

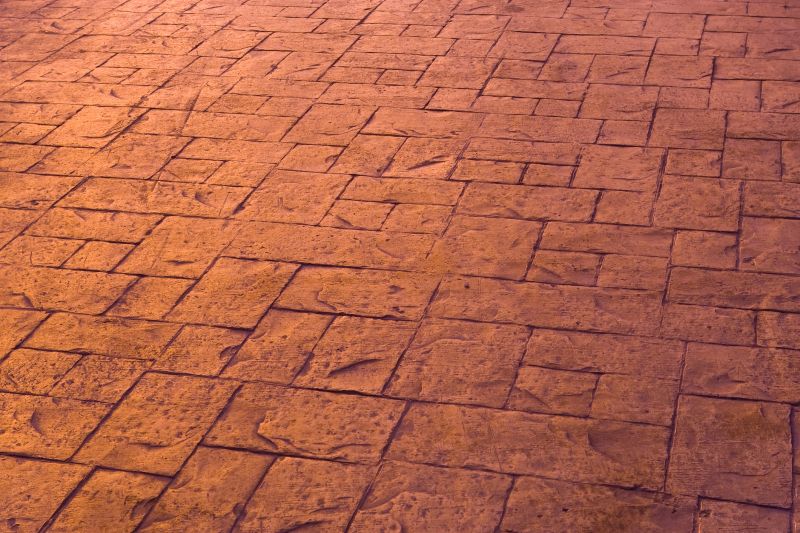

Stamped concrete service involves creating decorative patterns and textures on freshly poured concrete surfaces. It is a popular choice for patios, driveways, walkways, and pool decks due to its versatility and aesthetic appeal. The process includes applying stamps, coloring agents, and sealants to achieve a look that mimics natural stone, brick, or other materials. Proper timing and application techniques are essential to ensure durability, color retention, and a high-quality finish. Statistics show that stamped concrete can last for decades when properly installed and maintained, making it a cost-effective and visually appealing option for various outdoor surfaces.

Various patterns and textures can be applied to enhance curb appeal and complement outdoor designs.

Integral dyes and surface-applied color hardeners add depth and vibrancy to stamped concrete finishes.

Sealing protects stamped concrete from stains, weathering, and UV damage, extending its lifespan.

Finishes and colors that play nicely with Stamped Concrete Service.

Little measurements that prevent headaches on Stamped Concrete Service day.

A 60-second routine that keeps Stamped Concrete Service looking new.

A frequent mistake in Stamped Concrete Service and how to dodge it.

Small tweaks to make Stamped Concrete Service safer and easier to use.

| Aspect | Details |

|---|---|

| Best Seasons | Spring and early fall offer ideal conditions for installation. |

| Temperature Range | Between 50°F and 85°F is recommended for curing. |

| Weather Risks | Rain, extreme heat, and cold can impact quality and timing. |

| Curing Time | Typically 28 days before sealing. |

| Project Duration | Weather conditions influence scheduling and completion. |

| Sealing Timing | After full curing, usually around 28 days. |

| Installation Delay Factors | High humidity and sudden temperature drops. |

| Optimal Conditions | Dry, mild days with stable temperatures. |

For those interested in stamped concrete services, filling out the contact form provides an opportunity to discuss project specifics, scheduling, and customization options. Proper timing ensures the best results and longevity of the decorative surface, making it a worthwhile consideration for outdoor spaces in Chico, CA.